Horizontal Feed Mixer Design Pdf

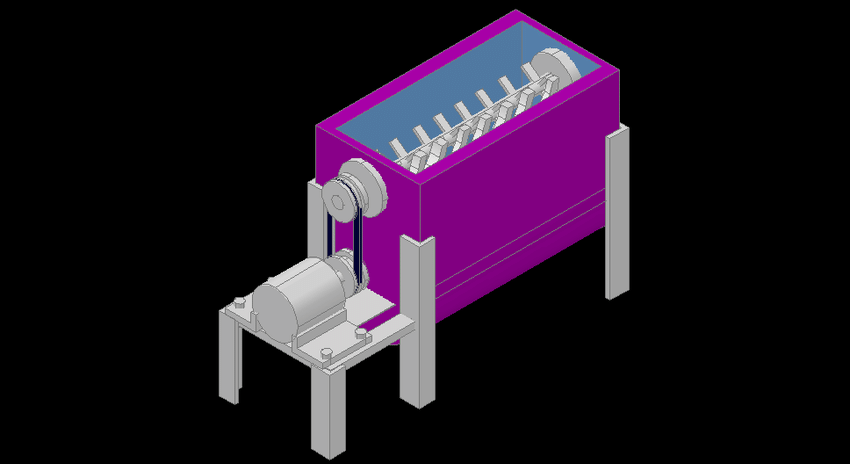

This paper presents the design and fabrication of a poultry feed industrial tumble mixer.

Horizontal feed mixer design pdf. The reversible drum mixer is similar to the non tilting mixer except that thesame opening is used to add the constituents and to discharge the aggregate. Davis mixers can be scale mounted. 519 529 7627 or 519 529 7000. Weigh each ingredient as it is added to the mixer.

Feed mixer can achieve the desired poultry feed mixing based on the following design specification of the various components of the machine. Another part of mixer design is the tank in which the mixer is used since. The design computation to handle a 25 kg mass of feed was done in the ms excel for proper machine design approach. Po box 158.

An animal feed mixing machine was designed fabricated and tested. The fundamental approach is straight forward design for power torque and speed then shaft loads and finally mixer dynamics. The combination of custom process and mechanical design necessary for mixers is unique for chemical process equipment. It can be a four point electronic scale system or a mechanical.

A wide variety of mixers are available for use in mixing components the selection of which depends mainly on the phase or phases the components exists such as solid liquid or gaseous phases. This is most popular when mixing feed containing molasses since this type of feed is difficult to convey and store. The machine was designed using proper material selection was done before the assembling and fabrication of parts. The shaft is designed to rotate at a relative speed of 800rpm and this is achieved by proper pulley selection to reduce the speed of the electric motor that has a speed of 1500rpm.

The second step in the design sequence is the mechanical design of the mixer components. Lucknow ontario canada. Mechanical design does not end with the shaft since strength and practical issues remain for the impeller. Some commonly used solid mixers as discussed by 4 includes.

Five 1kg samples collected from 10 odd numbered bags i e. Procedures corn soybean meal based diet formulated for broiler chicks d 0 to 17 diets mixed using a sprout waldron double ribbon mixer 0 5 2 5 and 5 0 min mash collected in 22 7 kg aliquots continuously online. 86386 lucknow line. Design the impact of decisions made at the process design step on the mechanical design requirements must be understood.

Tumbler mixers horizontal trough mixers vertical screw mixers etc. Horizontal mixer feeders stationary model trailer model manufactured by. The design computations to handle a 50kg mass of feed was done in the ms excel environment for proper machine design approach. Model hd30 heavy duty mixer with four point electronic scale.